Learning to Grade Softwood Dimension Lumber

What is Dimension Lumber?

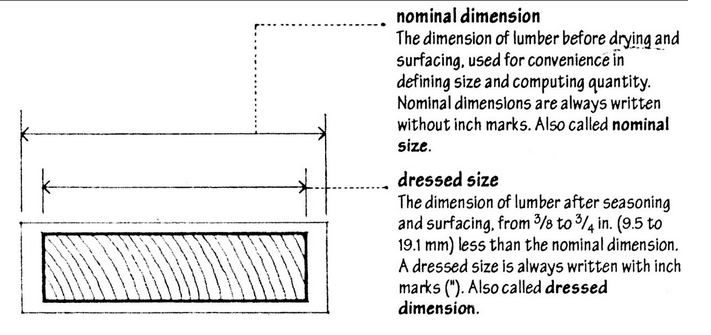

We have all seen buildings being framed with lumber. Do you know what type and grades of lumber are used in this framing process? Sometimes referred to as “dimensional lumber” or “framing lumber”, this wood is the mainstay of the housing industry in the US and Canada. Dimension lumber, as this lumber is formally labeled, is defined as lumber of nominal thicknesses of 2 inches TO LESS THAN FIVE inches and nominal widths of 2 inches and wider. It is smoothly surfaced softwood lumber that is sold and marketed by the “nominal sizes”, rather than the real final standard surfaced sizes, which are actually somewhat smaller than nominal sizes. In other words, lumber’s nominal dimensions are larger than the actual standard dimensions of finished lumber.

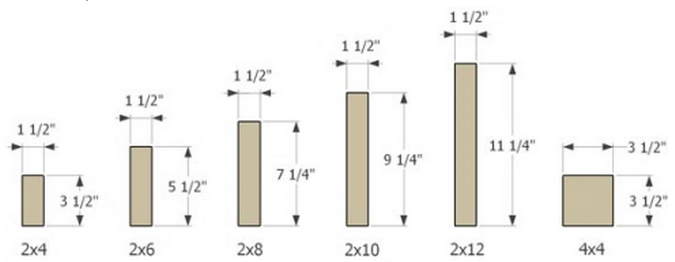

Historically, the nominal dimensions were the size of the green rough (unfinished) boards that eventually became smaller finished lumber through drying and planing (to smooth the wood). The actual size of Dimension Lumber is often a source of confusion for the lay person who when purchasing a 2×4 expects a piece of wood to be a full 2” x 4”. The drawing below shows the actual standard finished sizes of dimension lumber. Note that 2×4 and 2×6 are ½” less than nominal in width, and 2×8’s through 2×12’s are ¾” less than nominal in width. As you can see, all 2” dimension lumber is actually 1 ½” thick.

So, Dimension Lumber is primarily a size classification for a certain type softwood lumber product that is graded by a standard rule. This lumber is intended for use as framing members such as joists, planks, rafters and studs for building wood framed structures. 2×4’s through 2×12’s and all 4×4’s are common examples of Dimension Lumber.

There are two groups of people that want to understand how dimension lumber is graded, those using it and those producing it. The producers of dimension lumber will be very knowledgeable of how the lumber is graded and have access to training methods that the lay person does not. For many of those using framing lumber, the grading process and application of the rules remains a mystery.

Where Do Softwood Lumber Grade Rules Come From?

The rules for Softwood Lumber are written and published by the American Lumber Standard Committee approved Rules Writing Agencies, which are regional in nature, as their rules were originally developed for certain species and/or species mixes in their part of the country. Each of the regional agencies has grades for products that are uniquely suitable to the species in that area.

Softwoods have a wide range of applications and are found in such products as building components like framing, and roof trusses, but can also be found in windows, doors, furniture, siding, trim, flooring, and boards, so softwood grades can be based on appearance and/or strength. For the most part Softwood lumber grades are divided into three basic categories; appearance products like siding and flooring, factory and shop grades intended for remanufacturing purposes like windows and doors, and structural grades like dimension lumber, visually and/or mechanically graded for primarily for strength where appearance is a secondary consideration. These classifications are broad use categories with some overlap, and vary a little by regions of North America.

There is however, one main overlap, the grade rules for dimension lumber. These rules are virtually the same for any species because they are all graded using one set of rules, – the National Grading rule for Dimension Lumber or the NGR. In the USA the grading rules for 2” dimension lumber are established by a committee of lumber industry experts appointed by the American Lumber Standards Committee (ALSC) through the Department of Commerce. In Canada, the National Lumber Grades Authority (NLGA) is responsible for the establishment of Canadian lumber grading rules and standards and publishes the NGR in the NLGA Standard Grading Rules. Allowable stress ratings are published for each grade, and vary by species or species mix, as are evidenced in span tables.

Learning to Grade Dimension Lumber

Learning to grade dimension lumber on the production line can be a time consuming and challenging task. Traditionally, grader training takes place at the mill. Potential candidates are sometimes screened based upon their level of interest, ability to deal with simple math, and the willingness and ability to study and memorize the rules. In the US, mills are primarily responsible for developing graders with help provided by the Inspection Agency staff during lumber grade audits or specially scheduled training visits. This type of training has not been standardized. In Canada, the potential grader may be required to attend off site grading classes which are provided by the regional Grading Agencies to prepare students and to award grading tickets that signify successful completion of the training course. In this way, training can be delivered in a more organized fashion and tends to be more efficient for the trainee and the instructor, but it also introduces extra expenses in term of travel time and lodging. These courses are usually only available to producing mill employees.

Characteristics in Dimension are limited by the effect on strength properties, so the knots and holes are evaluated by the percent of the cross section that they occupy rather than the size on the face. Wane allowances are generous in Dimension because wane has very little effect on strength. Shake Checks and Splits have little effect on bending or compression strength so these defects and characteristics are limited with this in mind. There is a lot of material to absorb when learning to grade. Study alone is not enough; the mill grader must also learn to apply this knowledge on the production line and at high speeds. The correct application of the rules on the grading chain can only come from experience. One must learn and improve through practicing on the chain, reviewing their decisions during inspections, and working to eliminate mistakes and refining decisions over time with the help of the instructor. For the production line grader the challenge is in the speed at which they can make accurate decisions on the grade, and the correct length trimming decisions required for maximizing the value of each piece.

How can You Learn to Grade Softwood Dimension Lumber

If you want to learn to grade dimension lumber and you are not a potential grader at a mill, then what are your options? Up until now there weren’t many viable options. There was no complete reservoir of knowledge and materials other than the published Agency Rule Books which contain the NGR, some separate training manuals, tip sheets, and shorthand pocket guides developed independently by the experienced lumber inspectors and QC technicians at different mills and inspection agencies across North America. These tools, combined with face to face training and coaching by experienced lumber graders and inspectors, providing on the job and/or classroom sessions for mill employees, has been the only source of training, and these training practices were targeted to the mill grader. Until now!

SPIB eLearning Courses for 2” Dimension Lumber

The Southern Pine Inspection Bureau has recently introduced a series of online courses originally designed to enhance and speed up the traditional training methods used for dimension lumber graders in all producing regions of the US and Canada. With these SPIB eLearning courses you can obtain all of the essential training materials in a very systematic manner; starting with the fundamental terminology, the definitions and illustrations of the defects, the tools for understanding fractions and how they apply to the edges and width of lumber, how to read a tape measure, how to measure different shapes of knots, how to apply each grade rule, and even how to judge the size of knots without measuring. These courses make it efficient for anyone to learn and understand grading concepts and all the grade rules for Softwood Dimension Lumber.

If you are a buyer, seller or end user of framing lumber and you want to thoroughly understand how dimension lumber is graded, then these courses are for you. You won’t become a production line grader by taking these courses alone. For that you need the tutoring of experienced lumber graders and the hands on and face to face training that must take place in the lumber shed and on the grading chain. You will, however, completely understand the grading rules and how they are applied to lumber, and with a little practice, which is also provided within these courses, you can become quite knowledgeable and capable of determining the grades of dimension lumber.