What is Wood Grain – Part 2

In our first Blog, “What is Wood Grain’’, (May 12, 2016), we learned that one way the term “wood grain” can be used is to describe the density of the wood as it relates to structural properties of dimension lumber. We learned that the closer together the annual rings are, and the higher the percentage of summerwood, the greater the density and the greater the strength of the wood. Higher wood density is a grading rule requirement for certain higher grades of Southern Yellow Pine Dimension Lumber, whereas low-density pieces may have to be segregated into lower grades of dimension lumber.

Now let’s look at some other ways that the words “wood grain” are used to describe several other characteristics of wood.

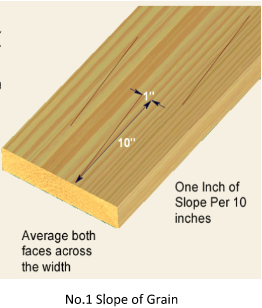

Slope of Grain

The term slope of grain relates to the direction of fibers compared to the edges of a piece. The main problem with an excessive slope of grain in lumber is that it reduces the strength, it may cause warping with a change in moisture content, and it makes it difficult to dress lumber smoothly when planing against the grain.

In lumber grading, a slope of grain is expressed by the ratio between the grain from the edge or long axis of the piece and the distance in (inches) within which this slope occurs.

The steeper the slope the greater potential for affecting the strength of the piece. For example in No.1 dimension the Slope of Grain, when measured this way, is limited to 1” over 10” while in No.3 the limit is 1” over 4”. That is how we grade the slope of grain that we can see on the surface of the wood.

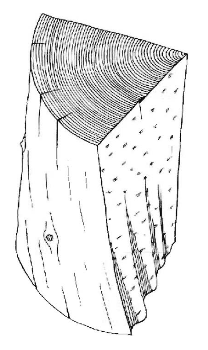

However, the true slope of grain in wood is a more complicated subject. There is no simple and easy way of measuring it. Since the true slope of the fibers on the inside of a piece of wood cannot be seen unless you split the wood, and it cannot be measured by examining only one surface of the piece.

To determine the true slope within the cross section, it is necessary to measure the component slopes separately in two planes, more or less at right angles to each other and parallel to the direction of the fibers. The component slopes together then would give a combined, or true slope.

Spiral grain

Spiral grain is caused by the winding growth of wood fibers about the trunk of the tree instead of vertical growth. In sawn wood, spiral grain can be defined as fibers lying in the tangential plane of the growth rings, rather than parallel to the longitudinal axis of the product.

Spiral grain in sawn products often goes undetected by ordinary visual inspection. A visual method of determining the presence of spiral grain is to observe the angel of pores, rays, and resin ducts on a flat-sawn face. Checks that develop during drying on flat-sawn surfaces will follow the fibers and indicate the slope of the fiber. Spiral and diagonal grain can combine to produce a more complex grain.

Cross grain

Cross describes wood in which the direction of the fibers (not annual rings) are at an angle with the sides of the piece. Cross grain may include spiral grain where fibers wind around the trunk of the tree.

Cross grain can be quite localized as a result of the disturbance of the grain direction by a branch. This is typically referred to as, a local deviation, or local slope of grain, and may be present even though the branch (knot) may have been removed by sawing.

The degree of local cross grain may often be difficult to determine. Any form of cross grain can have a negative effect on strength.

Diagonal grain

Diagonal grain is cross grain caused by growth rings that are not parallel to one or both surfaces of the piece. Diagonal grain is produced by sawing a log with a distinct taper parallel to the central axis of the tree. Diagonal grain also occurs in lumber sawn from crooked logs or logs with butt swell.

The Slope of Grain, Spiral Grain, Cross Grain, and Diagonal Grain are more or less technical terms used to describe how grain can affect the strength properties, and to a lesser extent, the appearance, of a piece of lumber.

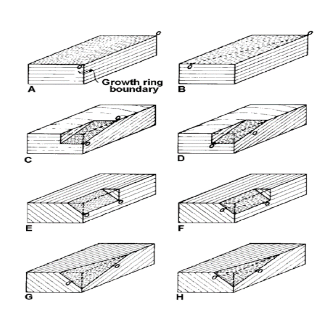

Blocks A through D have radial and tangential surfaces; E through H do not.

Specimens A and E contain no cross grain; B, D, F, and H have spiral grain, D, G, and H have diagonal grain.

Mechanical Properties of Wood David E. Kretschmann, Research General Engineer

Wood Grain; Texture, Appeal, and Appearance

In fine woodworking and finishing wood grain can refer to the texture of the wood, – the relative size, as well as the amount of variation in size, of the wood cells. These influence how the wood looks and feels to our senses. It’s the cells and how they’re arranged, the size and distribution of pores, which make the difference between what we perceive as smooth fine-textured wood or rough coarse-textured wood.

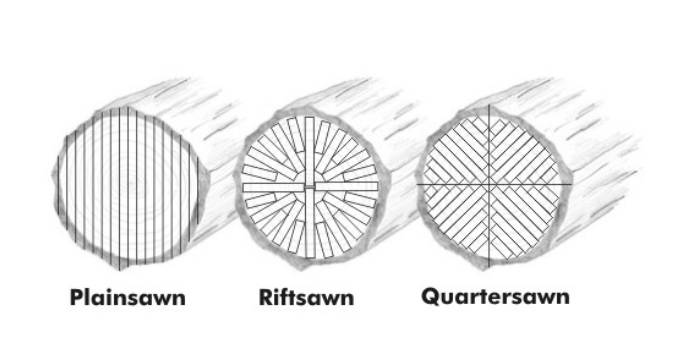

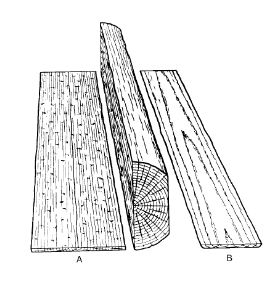

Other terminology related to the appearance of wood, when working and finishing, has to do with the angle of the saw relative to the growth rings. Lumber sawed with the annual rings, forming an angle of 45” or more with the wide faces is often described as edge-grain, vertical grain or rift-sawn in softwoods. In hardwoods, this angel of sawing is often referred to as quarter-sawn or comb-grained. The way the lumber is sawn from the log has a marked effect on the appearance of the grain on the surfaces of each piece.

The terms “flat grain” or “plain-sawed” are also used to describe lumber in which the annual rings are at different angles with the wide faces of the piece. As you can see in the diagram the flat grain and plain sawn faces will have very different looks, and to some extent, different strength properties.

- A) plain-sawed

- B) flat grain

As you can see the correct use of the term “wood grain” can be an ambiguous subject. “Grain” really is a confusingly versatile term.

A particular piece of wood may look beautiful or unpleasant; it can exhibit great strength or weakness, it may be smooth and fine-textured, or it may feel rough and unpleasant, all due to the character of its grain…

If you want to learn more about other characteristics of wood and how they affect the grades of dimension lumber check out the SPIB eLearning Courses on Dimension Lumber Grading. These courses make it efficient for anyone to learn and understand grading of Softwood Dimension Lumber.

The SPIB eLearning courses are the only way to learn how to grade Dimension Lumber without spending 100’s of hours in the lumber shed, on the production chain, and/or in the classroom with an experienced grader trainer.